Glidewell: Your Truly Digital Lab

Why Digital?

As a dedicated clinician, you’ve made it your mission to see to the health and confidence of every patient who walks through your door. Glidewell is similarly committed to helping more patients receive access to quality dentistry by helping dental practices thrive and take advantage of the newest in digital restorative services.

Our digital offerings can help you simplify and automate your clinical workflows; improve the consistency, predictability and accuracy of the restorative services provided to your patients; and save time and money that can be reinvested in your practice and your future.

Redefining What a Digital Lab Should Be

At Glidewell, we believe digital technology should improve your workflow without disrupting it. That’s why we offer entry points built around your current capabilities and needs, whatever those may be.

SCAN IT

Dentists who send digital impressions to Glidewell realize a number of benefits only a lab that receives over 100,000 scans a month could offer. We accept files from any intraoral scanner, provide specialized data optimization services and real-time feedback, and offer 3-day in-lab working times as a standard. Plus, model-free restorations produced from intraoral scans receive a discount of $20 or more per unit.

Mill it

Intraoral scanners also empower dentists to deliver same-day restorations using the glidewell.io™ In-Office Solution. By scanning, designing and milling in-office, practitioners can offer patients a single-visit restorative experience that minimizes time spent in the chair and reduces the risks associated with cross-contamination.

Ship It

For clinicians who have not yet invested in chairside digital technologies, or prefer to submit an elastomeric impression, Glidewell makes it possible to convert to a digital workflow when the case is received at the laboratory, using a suite of proprietary laboratory innovations collectively known as Glidewell Intelligent Manufacturing (IM).

SCAN IT: Your One-Stop Shop for Restorations from Digital Impressions

There’s a reason why dentists everywhere rely on Glidewell as their one-stop shop for digital restorations. We are trusted with thousands of digital impressions every day and support every scanner on the market, allowing clinicians to take advantage of the resources only the leading digital lab can offer.

Real-Time Review and Quality Check

Our dedicated digital technicians boast over 300 years of combined experience specializing in digital restorations. Our specially trained team evaluates the fidelity of each intraoral scan, verifying data integrity before cases enter production. This enables us to smooth out any data gaps or inconsistencies that may ultimately compromise restoration quality. Our experts are also available for real-time review of scan quality to support our digital doctors.

Fast 3-day In-Lab Turnaround

Our digital order process is optimized to get you your final restorations as quickly and efficiently as possible – in just 3 working days. Every digital impression goes through an extensive review process in our lab based out of Irvine, California, ensuring your restorations are expertly designed and fabricated all in one, streamlined workflow.

Grow Your Digital Practice

Watch your profits build as you spend less on impression materials and shipping supplies. When you submit a digital impression to Glidewell you save $40 on screw-retained implants, $20 per unit on model-free all-ceramic restorations, and $9 in shipping costs per case.

Send Your Case Your Way

To experience the Glidewell digital advantage, simply send us your next case using your delivery method of choice.

Ready to Start Scanning or to Acquire an Additional Scanner for Your Practice?

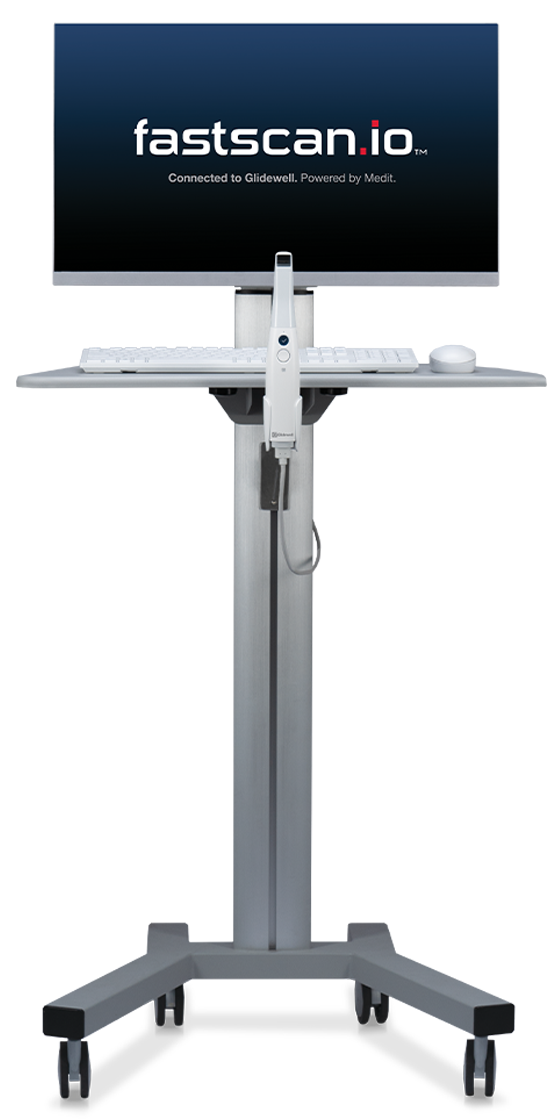

The fastscan.io™ Scanning Solution combines seamless connection to Glidewell to further simplify digital case submission with the advanced scanning technology of the Medit i700.

Additionally, the scanner is delivered complete with rolling cart and computer. The fastscan.io is an affordable, no fees solution for both those new to scanning and adding new scanning capacity to the practice.

MILL IT: Deliver same-visit BruxZir® Crowns

For dentists ready to bring their lab chairside and offer same-visit restorations, Glidewell proudly offers the glidewell.io In-Office Solution.

- Mill fully sintered BruxZir® crowns and bridges with no oven time required — just polish and cement, and you’re done.

- Let MarginAI™ and CrownAI™ do the design work for you so you can spend your time with your patients.

- You’re connected directly to Glidewell for training and support at any time.

- Love your scanner? Great — glidewell.io is an open system and works with your preferred scanning system.

What glidewell.io Users Have to Say

SHIP IT: Glidewell Intelligent Manufacturing Digitizes Your Case For You

With Glidewell Intelligent Manufacturing’s (IM) four-step process doctors can realize all the benefits of going fully digital without the investment or learning curve that might otherwise be required when implementing digital technology in the dental office. The nearly hands-free process is faster, more accurate and more precise — and all but eliminates the need for study models.

Step 1: Micro Ct Impression Scanning

Micro CT Impression Scanning enables the lab to digitize elastomeric impressions to eliminate errors introduced by traditional plaster models and provide for a faster, more accurate means of crown fabrication.

Step 2: Virtual Plaster Experience (Vpx)

In a conventional restorative process, incoming impressions are used to produce plaster models. With digital files of CT-scanned impressions, the plaster model process takes place in a virtual environment. This proprietary process is termed Virtual Plaster Experience (VPX). VPX software produces a three-dimensional image of a patient model based on the digitized impression file and enables a technician to perform die trim and margin marking operations digitally.

STEP 3: A.I.-Enhanced Restorative Design

Conventional restoration design relies on the technician to craft the features required to make that restoration unique. The process is time-consuming and can be subject to significant variation from one case to the next. With Glidewell IM initial restoration designs are automatically proposed by proprietary software that makes use of machine-learning algorithms and takes into account the morphology of the patient’s surrounding dentition. From there, the technician can quickly accept or modify the design as needed, further “teaching” the software along the way.

STEP 4: Augmented Production

The Glidewell IM production center is designed to fabricate patient-specific restorations at scale with unprecedented precision and consistency. This Industry 4.0 assembly is in essence a “smart factory” of the future that serves to minimize the inherent variability of human interaction with its nearly hands-free operation, while offering levels of efficiency and visibility never before seen in the dental industry.